Andreas Strobel

Head of Application Technology Department

T+49 5273 809-0

eub@agc.com

INTERPANE Entwicklungs- und Beratungsgesellschaft mbH

Sohnreystraße 21

37697 Lauenförde

Germany

Plasma &

Innovative plasma coating solutions from research and development to mass production – expertise in PVD and PECVD technology, delivered worldwide.

Plasma & Engineering

We conduct research and development for the AGC Group and solve application technology issues for our market partners.

Our development and consulting company (E&B)

Interpane Entwicklungs- und Beratungsgesellschaft GmbH (E & B) carries out intensive research and development work for the AGC Group and is also available to market partners to help solve technical application issues.

In addition to the core topic of ‘glass’, other new market segments are also being developed. Through co-operation with partner companies, E&B is developing new processes and systems in the areas of

Battery technology

Astronomy

Surface hardening

Textile finishing

etc.

INTERPANE Entwicklungs- und Beratungsgesellschaft mbH

Sohnreystraße 21

37697 Lauenförde, Germany

Hugues Wiame, Dominik Waldeyer

T+49 5273 809 0

eub@agc.com

Areas of responsibility

Application technology

- Consulting on the constructive implementation of innovative glass applications in building construction

- Consulting on building physics and application-related problem solving, taking into account relevant standards and guidelines

- Measurement and calculation of the technical properties of insulated glass combinations in collaboration with our physical laboratory

- Technical product and material analysis for insulated glass applications

- Continuous auditing of INTERPANE production facilities

- Development and improvement of glass products for environmentally friendly, future-oriented, energy-saving glass applications

Andreas Strobel

Head of Application Technology Department

T+49 5273 809-0

eub@agc.com

Dr. rer. nat. Hansjoerg Weis

Head of Coating Development Department

T+49 5273 809-0

eub@agc.com

Areas of responsibility

Coating development

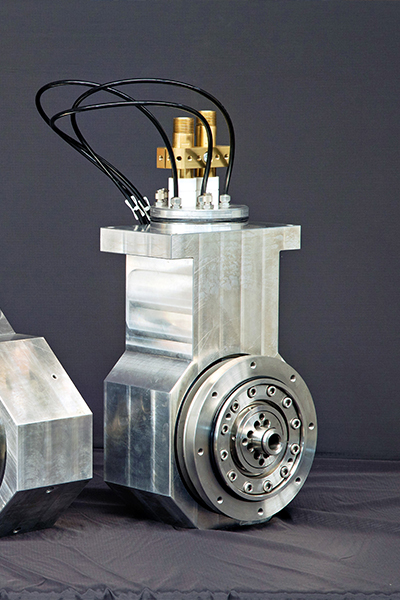

- Research and development of innovative coating systems and products

- Analysis and assessment of new advancements in coating technology

- Fundamental research on magnetron sputtering

The coating development department has laboratory sputtering systems equipped with online analytical systems. The design of the system not only enables the rapid realization of new coating systems, but also allows all system components, such as cathodes, to be easily modified and new models to be tested. In addition to the laboratory coating system, the department is also equipped with highly developed analysis and modeling programs. The optical properties of complex coating systems can be predicted very precisely, which means that laboratory results can be transferred to production very quickly.

In cooperation with various research institutes, fundamental theoretical issues relating to new developments and processes are investigated, ensuring that the Interpane Group always remains at the forefront of innovation.

In close cooperation with the coating companies of the Interpane Group, the results of the research work are quickly turned into products. The exchange of experience leads to constantly growing expertise in the field of float glass coating.

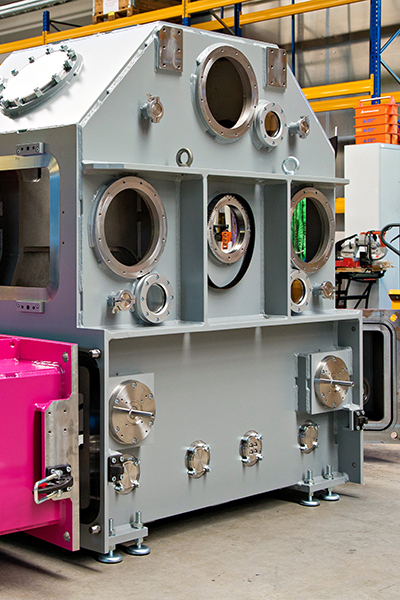

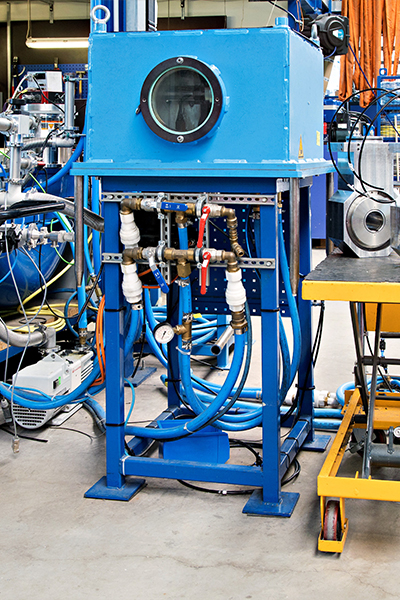

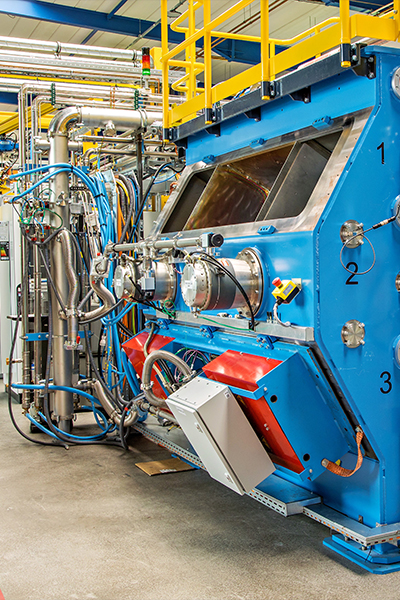

Various pilot coating systems are available in our own technical center for the development of new products:

- HIPCoater

- VIPCoater

- MultiVIP

- R2R Coater for testing coating systems on rollable substrates (fabrics, films, thin metal foils), roll width: max 160 cm

- Flat glass washing machine

Areas of responsibility

Machine and plant engineering

- Mechanical engineering implementation of the coating technology within the AGC Group

- Conceptualization, design, pre-assembly, installation, and commissioning at the customer’s location

- Technical support of the coating systems in the INTERPANE facilities

- Maintenance and service of coating plant components

- Relocation and disassembly of glass processing systems

- Upgrades, retrofits, extensions, component replacement on existing coating systems

- Re-engineering

Additional tasks include, for example, the setup of insulated glass operations within the AGC Group.

Marc Ewers

Head of Mechanical and Plant Engineering Department

T+49 5273 809-0

eub@agc.com

References for coating facilities

Batch facilities

- 1982 BCD 14 INTERPANE Plattling

- 1985 BCD 02 INTERPANE Lauenförde

- 1986 BCD 16 INTERPANE Coating, USA

- 1986 BCD 12 INTERPANE Lauenförde

Laboratory facilities

- 1988 VIP 1200 INTERPANE Lauenförde

- 1990 VIP 1200 FhG ISE, Freiburg

- 2002 FhG ISE, Freiburg

- 2002 INTERPANE E & B, Technikum Gaschrom

- 2022 INTERPANE E&B, Roll to roll system for coating coil substrates

- 2023 Laboratory coating system with PECVD technology, Bozeman, North America

- 2023 Roll to roll substrate coating system HAWK, Göttingen

Continuous coating facilities

- 1993 INTERPANE Plattling

- 1994 INTERCAM, Cayirova, Turkey

- 1995 INTERPANE Lauenförde

- 1996 INTERPANE Solar, Lauenförde

- 2000 INTERPANE Plattling

- 2002 INTERPANE Solar, Lauenförde

- 2003 HIPC03 Seingbouse, France

- 2007 HIPC04 Bursa, Yenisehir, Turkey

- 2008 HIPC05 Osterwedding

- 2010 VGCP04, Plauen

- 2012 HIPC08 LG Hausys, South Korea

- 2013 HIPC09 AGC Klin, Russia

- 2016 HIPC10 Yanbu, Saudi Arabia

- 2017 HIPC11 Cikampek, Java/Indonesia

- 2018 HIPC12 Church Hill, North America

- 2020 Eastman, Dresden

- 2020 VIPC06 Suzhou, China

- 2024 VIPC04.2 Roccasecca, Italy

Insulating glass companies

- 1991 INTERPANE Belgern

Astronomy mirror coating facilities

- 2022 ESO M1CP1 and M1CP2, Paranal, Chile

- 2024 IAC, IATEC Teneriffa, Spain

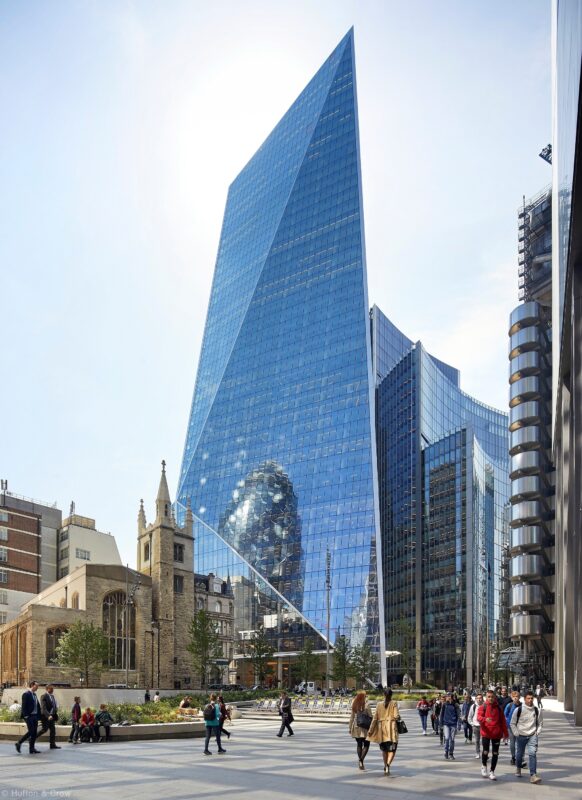

Contemporary architecture is glass architecture. Architects worldwide are making bold statements with generously glazed surfaces. Ever more bold architectural designs and higher demands on the energy balance and sustainability of buildings require innovative glass technologies. AGC Interpane supports you with decades of project expertise and high-end solar protection glass from the Stopray, ipasol and Stopsol brands – with certified quality in accordance with EN ISO 9001, EN ISO 50001, OSHAS 18001 and EN ISO 14001.

Energy-efficient and sustainable buildings are a must today. Thermal insulation glass with Ug values below 1.0 W/(m²K) brings plenty of daylight into the room and enables solar energy gains in the cold months. At the same time, our iplus coating ensures that heat is reliably retained in the room, so that even larger glass surfaces can be realized with our double or triple glazing without any loss of comfort. Iplus thermal insulation glazing can be combined with many other functions such as solar control, sound insulation and safety glass.

Elements made of glass shape the image of modern architecture. The opportunity to use our ipasafe safety glazing as a structural element enables architects and facade builders to realize innovative designs. Ipasafe glazing combines active, passive and constructive safety properties: it provides active protection against burglary, bullets and damage to people, passive safety to protect against injuries caused by glass breakage and constructive safety through high residual stability and residual load-bearing capacity in the event of failure.

The global demand for oversized glazing products is increasing. AGC Interpane’s ‘Giga Lites’ are the go-to solution for architects who want to create exclusive glass architecture by cladding entire facades with just a few large glass panels. Measuring up to 19.00 x 3.21 meters, these giant glass panels are among the largest functional coated glazing products available worldwide, with a maximum thickness of 20 millimeters.

Environmental protection in its entirety requires not only noise protection, but also the protection of natural resources. Therefore, a modern soundproof insulated glass must also reduce heat transmission losses. That’s why our ipaphon soundproof glass is standard-equipped with our high-quality iplus coating. All types can be combined with almost all Stopray and ipasol coatings for additional functions.

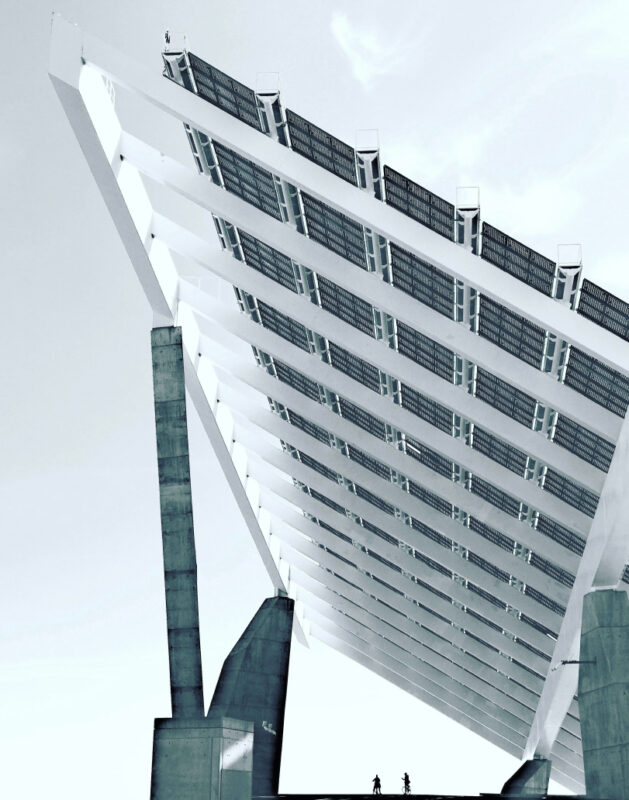

Glass is a crucial component in both new and traditional solar applications. Anti-reflective coatings enhance energy transmission through the glazing, allowing collectors to operate more efficiently at shallower angles during morning and evening hours. With the new SolarColor brand, we design GIPV (building-integrated photovoltaics) attractively to meet the needs of architects and façade planners – with high colour flexibility and excellent energy yield at the same time. In contrast, building-integrated photovoltaics (BIPV) in glass is offered by SunEwat XL, which boosts the energy balance of every building through active power generation in the facade, leading to a rapid payback on investment for new and refurbished facades.

Frosted or glossy, translucent or opaque, high-reflective partial coatings, digital and screen prints or ceramic digital prints of high-resolution motifs – design glasses enhance walls and furniture in interior design and sometimes entire facades in exterior design. Discover the variety of our solutions.

Our products

We have been known as a brilliant glass finisher for over half a century. In our modern project centres in Plattling and Lauenförde, AGC INTERPANE ARCHITECTURAL GLASS GmbH gives your glass special functions through perfect coatings and then guarantees excellent sun protection, thermal insulation, soundproofing, high security and much more.

We are happy to advise you

Perfect advice for a successful collaboration

Application technology

Machine and plant engineering

Marc Ewers

Head of Mechanical and Plant Engineering Department

T+49 5273 809-0

eub@agc.com

INTERPANE Entwicklungs- und Beratungsgesellschaft mbH

Sohnreystraße 21

37697 Lauenförde

Germany

Layer development

Dr. rer. nat. Hansjoerg Weis

Head of Coating Development Department

T+49 5273 809-0

eub@agc.com

INTERPANE Entwicklungs- und Beratungsgesellschaft mbH

Sohnreystraße 21

37697 Lauenförde

Germany

Sales & distribution

Hugues Wiame

CEO

T+49 5273 809-0

F+49 5273 809-411

eub@agc.com

Secretariat:

Kerstin Sorby

INTERPANE Entwicklungs- und Beratungsgesellschaft mbH

Sohnreystraße 21

37697 Lauenförde

Germany