AGC Interpane: ENI Headquarter, Milan

Geologically inspired

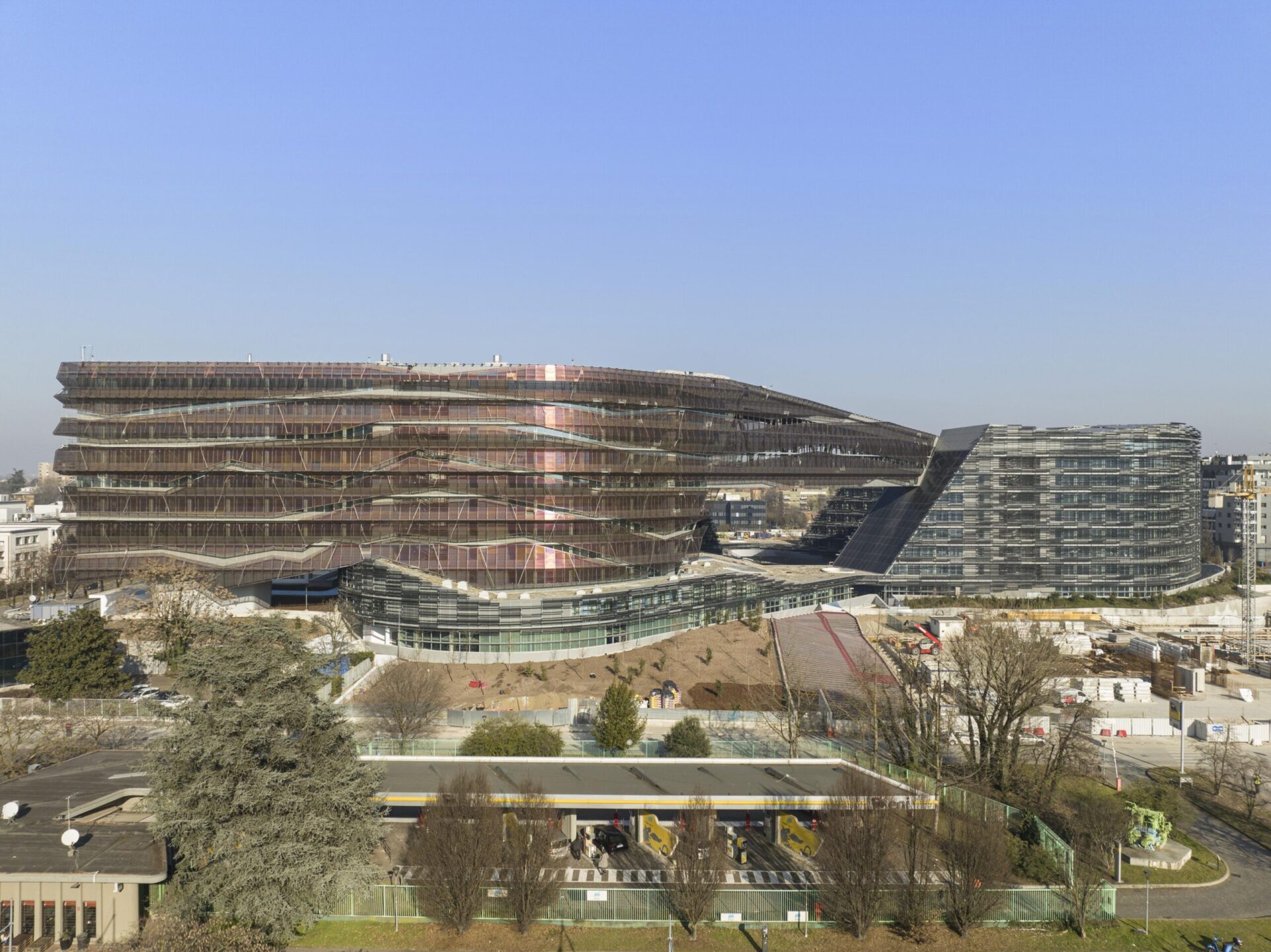

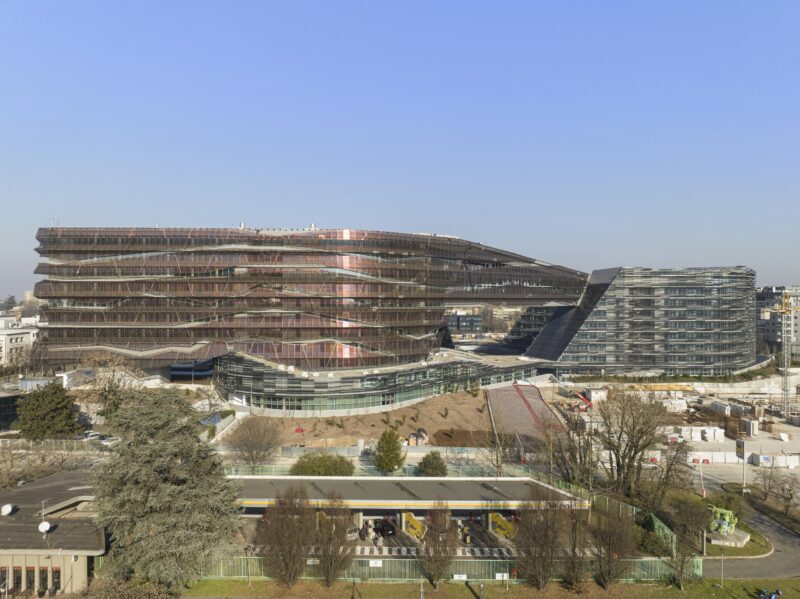

The “ideal city” of Metanopoli, conceived by Enrico Mattei back in the 1950s, has now been given a prominent addition in the form of the “VI Palazzo ENI”: three horizontally aligned “towers” connected by futuristic skybridges nestle flat against the geography of the industrial landscape on the south-eastern edge of Milan and frame a large, central square.

The new headquarters of Italian energy giant ENI was designed as an innovation campus and dedicated to energy research and production. The “LEED Gold” award-winning complex, designed by Morphosis Architects in collaboration with Nemesi Architects, offers a gross usable area of 65,000 square meters – enough space and flexibility for 4,600 modular workstations. The “metamorphic” glass facade (Stopray Vision 60 and Stopray Grey 25 from AGC Interpane) with a metal sun and glare protection screen in front on the south side controls the light conditions inside and provides effective heat protection in summer.

In 1952, Enrico Mattei, chairman of the newly founded ENI (Ente Nazionale Idrocarburi), now a multinational energy company, commissioned urban planner Mario Bacciocchi to draw up a master plan for a new area in the municipality of San Donato Milanese. The result: Metanopoli, a garden city for ENI employees. Since then, many prominent office buildings have been erected, the first in 1955, a hexagon by Marcello Nizzoli and Gianmario Oliveri. A star-shaped building by Marco Bacigalupo and Ugo Ratti followed in 1962. In the 1970s, the third palazzo was built, marked by dark red bands. In 1984, the IV Palazzo was added, with an austere façade and in the 90s an office building with green glass façades by Roberto Gabetti and Aimaro Isola. The rather straightforward concept was replaced by the V. Palazzo, a round building with terraced gardens by Gabetti and Isola. The most recent project, the new ENI headquarters, continued this development with a fluid-like form as a metaphor for the transformation of material into energy. The project was designed by US architecture firm Morphosis Architects under the direction of Pritzker Prize winner Thom Mayne, in collaboration with Nemesi Architects. At eleven storeys, the “Icon Tower” is the tallest building, which also houses the canteen – with an area of 5,600 square meters for 1,100 guests. The “Landmark Tower” is the largest with 23,700 square meters on nine floors. The “Skygarden Tower”, located in the middle, houses a conference center with 360 seats, a cafeteria and a catering and conference area. In the upper part, an evergreen panoramic garden provides temporary respite and ensures less fine dust and shading of the thermal mass. There is ample parking space in the shared basement of the complex, which removes vehicles from the cityscape.

Probably the biggest architectural challenge was the bridges and transfer structures between the buildings, bolted metal constructions whose main membranes were partly pre-assembled and then raised. “Icon” and ‘Landmark’ are connected on the seventh floor by an 85-metre-long steel bridge that varies in width between around 15 and three meters, as well as in height, starting at a whopping 20 meters at the Icon and six meters where it docks at the Landmark. The bridge transfers the vertical load on the Icon to tapered reinforced concrete piers and the reinforced concrete partition walls on the Landmark. The Icon is also connected to the Skygarden building on the second floor via another metal bridge, which is around 68 meters long. This consists of two spans with a clear span of around 15 meters and one with a span of 38 meters. Joints at the ends of the bridge make the structure independent of the Icon and Skygarden.

Sustainability and energy performance

The new Eni headquarters was developed with the clear goal of high sustainability and energy efficiency and has achieved LEED Gold certification (Leadership in Energy and Environmental Design). The high-performance double-skin facade also contributes to this. Inspired by geological formations, which are also reflected in the layered shape of the buildings, the front outer shell consists of micro-perforated metal sheets (55 percent perforated) that emerge sculpturally from the structure. The copper-coloured metal panels were organized in panels at different angles. The bluish shimmering parts consist of panels of horizontally drilled thin sheets (55 percent perforated) of different dimensions and inclinations. The actual building envelope is formed by a complex glass facade equipped with highly efficient and partially curved solar control glazing from AGC Interpane, sealed with structural silicone – a so-called “Structural Sealant Glazing System”. In large parts of the facades, around 17,000 square meters of “Stopray Vision-60” protect the building from overheating in summer with a g-value of 33 percent, thus reducing the need for air conditioning. At the same time, it transmits a high 59% of visible daylight, for maximum daylight utilization and bright rooms all year round. The light reflection is relatively low at 15 percent to the outside and 17 percent to the inside – this and the high color neutrality (Ra = 95) favor an undistorted view. With a Ug-value of just 1.0 W/(m2K), the double-glazing provides excellent protection against rooms cooling down at low outside temperatures. AGC Interpane used toughened and tempered base glass (with heat soak test) for the glass structure. The special feature: it was only coated to a fixed size after the glass had been tempered and the complete laminated safety glass packages had been laminated – with a specially customized Stopray Vision 60 coating. The tempering process could therefore be carried out with more even cooling and heat distribution, so that the glass is even flatter – this prevents unsightly “distortions” in the aesthetic effect of the facade. For curved parts of the building, for example in the two-storey high lobby (around 600 square meters), the solar control coating was even “bent along”. AGC Interpane used around 3,600 square meters of “Stopray Grey 25” (a project layer outside of the standard delivery program) in the “Black Facade”, the eye-catching angled sections of the building, with a toughened and solar control-coated monolithic pane on the outside and laminates of toughened glass on the inside for fall protection. With an extraordinarily low g-value of just 12 percent, the facade, which deliberately appears dark from the outside, blocks out the majority of the sun’s rays, which are particularly prominent here during the day. With a daylight transmission of just 15 percent, this part of the facade acts like “sunglasses” for the headquarters. AGC Interpane supplied 18,000 square meters of printed mono-laminated safety glass for the building’s opaque balustrades, which are used to provide additional shading for the building’s thermal mass.

All solar control glazing in the Stopray family has been awarded the “Cradle to Cradle” sustainability certificate in silver and is also available in “low carbon” versions as part of the AGC Group’s new CO2-reduced production. By using them, architects and planners improve the classification of their buildings in environmental certifications according to DGNB, LEED, BREEAM etc.

Construction board

Objekt

ENI Headquarter, Mailand

Bauherr

Webuild S.p.A. (Italien)

Mieter

ENI (Ente Nazionale Idrocarburi)

Objektadresse

V.le Alcide de Gasperi, 2, 20097 San Donato Milanese MI, Italien

Architektur

Morphosis Architects und Nemesi Architekten

Fassadenbau

Bodino (Turin), im späteren Verlauf Simeon

Glasprodukte

Stopray 60 Vision, Stopray Grey 25 und bedruckte Brüstungsverglasungen

Glasveredelung und Isolierglasbau

AGC Interpane

AGC Interpane: ENI Headquarter, Milan

Public relations

DownloadsDownload all

The new ENI headquarters in Milan is the latest building in Enrico Mattei's "ideal city."

The new ENI headquarters in Milan is the latest building in Enrico Mattei's "ideal city."

Photo: Roland HalbeJPEG | 772.91 KB | 5000px x 3751px The new ENI headquarters in Milan is the latest building in Enrico Mattei's "ideal city."

The new ENI headquarters in Milan is the latest building in Enrico Mattei's "ideal city."

Photo: Roland HalbeJPEG | 1.65 MB | 5000px x 3758px The new ENI headquarters in Milan is the latest building in Enrico Mattei's "ideal city."

The new ENI headquarters in Milan is the latest building in Enrico Mattei's "ideal city."

Photo: Roland HalbeJPEG | 2.23 MB | 5000px x 3751px The new ENI headquarters in Milan is the latest building in Enrico Mattei's "ideal city."

The new ENI headquarters in Milan is the latest building in Enrico Mattei's "ideal city."

Photo: Roland HalbeJPEG | 2.44 MB | 5000px x 3744px

Copyright notice

Reprint free of charge

Specimen copy requested

AGC Interpane holds all rights to the images in this press section/image database. AGC Interpane permits the use of these images without compensation only when used for their reproduction and dissemination for editorial and press purposes. The images may only be used when shown together with the proper placement/printing of the copyright note “Photo: AGC Interpane”. If an image features a copyright note other than this one, that respective note must be used instead. Any other use of the images, especially their sale and use for advertising purposes, is strictly prohibited. Voucher copy requested.